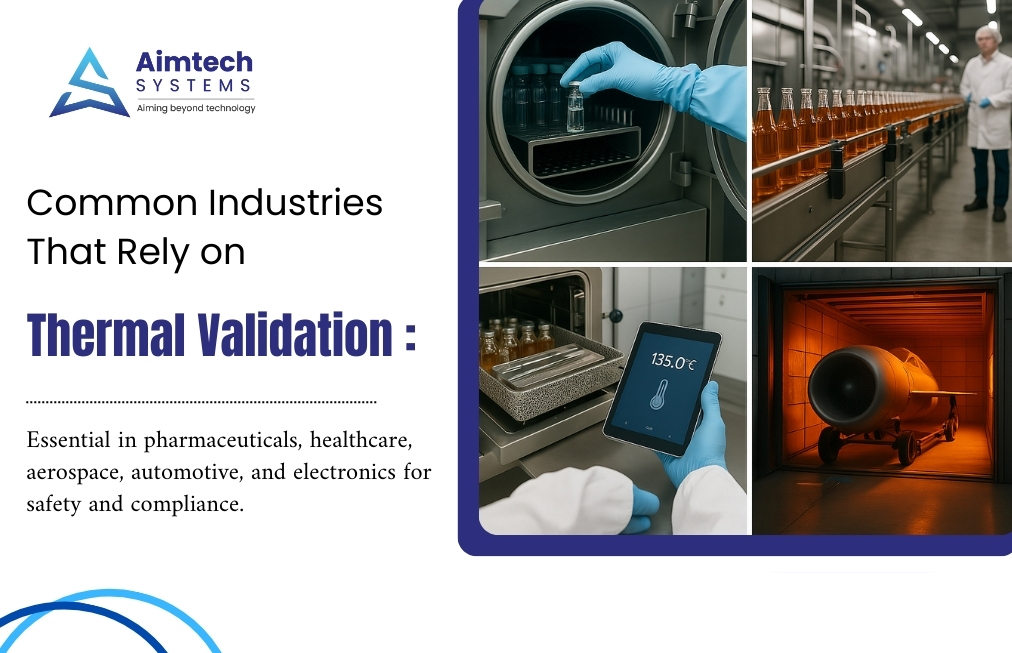

Common Industries That Rely on Thermal Validation

Introduction In many industries, temperature control is a critical factor that directly impacts product quality, safety, and regulatory compliance. Thermal validation is the process of ensuring that temperature-sensitive equipment—such as sterilizers, ovens, freezers, and incubators—operates consistently within required limits. This process is crucial in industries where deviations in temperature...